CassavaTech's Integrated Biogas Power Plant Project

The Ethanol Plant's automatic backup Biogas Power Generation (BPP) consists of 14 x 1MWh installed Biogas Genset units from MMW Czech. The Genset are designed and installed to operate independently for each secteur of the Ethanol Plant to maximize availability and efficiency 24/7, and minimize operation expenses. Besides, each independent unit shall not require any licensing due their small installation capacity which does exceed 1 MW. As automatic backup power supply units to backup the power supply from the national grid, their primary function is to secure the uninterrupted power supply to the Ethanol Plant facilities.

Why Biogas Power Plant?

For the purpose of bankability, the CassavaTech's High Quality Ethanol Production Plant shall be provided with its own integrated backup power generation plant, securing its uninterrupted operation 24/7. Hence, the Ethanol Production Plant can be powered with Biogas Power Plant (BPP) or a Hydroelectric Power Plant.(HPP). Our studies have demonstrated that BPP is highly more bankable and more technoeconomically feasible than HPP. Besides, the BPP and more ecologically and environmentally friendly that HPP due added value to protection and development of the ecosystem, transforming wastes to energy and using residues as biosolids fertiliser for the Cassava Farm.

BPP Main Specifications

Code |

Systems |

Paratmer / Name |

Value |

| CASTEC-002-BIOGPP-01 | Biogas Power Plant | Power Plant Total Installed Capacity | 14 MW |

| CASTEC-002-BIOGPP-02 | Engine | Engine TCG 2020 V12 | 1.2 MWh (1,200kW) |

| CASTEC-002-BIOGPP-03 | Fuel System | Fuel Consumption (Biogas) | 2,489 kW (+5%) |

| CASTEC-002-BIOGPP-05 | Generator | Generator Efficiency | 97% |

| CASTEC-002-BIOGPP-06 | Cooling Tower |

Cooling Water Consumption |

139 dm³ (litres) / engine |

Plant Key Perforomace Indicators (KPI)

Biogas Power Plant (BPP) KPIs cover Operational Efficiency (MWh/hr output, uptime, feedstock consistency), Financial Viability (ROI, Net Profit Margin, Cost per unit of biogas/energy), Environmental Impact (GHG emissions, nutrient recycling), and Feedstock Management (supply reliability, degradation efficiency) to assess performance across energy generation, waste treatment, and nutrient recovery. Key metrics include daily CHP output, feedstock-to-energy conversion rates, operational costs (OPEX), and compliance with safety/environmental standards.

Operational KPIs

-

- Production Output. MWh of Combined Heat & Power (CHP) or cubic meters of biomethane generated per hour/day.

- Plant Uptime/Availability. Percentage of time the plant is operational.

- Energy Conversion Efficiency. Energy output relative to feedstock input.

- Feedstock Consistency. Reliability and quality of the input material.

Financial KPIs

-

- Return on Investment (ROI) & Internal Rate of Return (IRR). Measures overall profitability.

- Operating Cash Flow (OCF). Cash generated from normal operations.

- Net Profit Margin. Profitability relative to revenue.

- Cost per Unit. Cost to produce a unit of biogas or energy (€/MWh).

Environmental & Sustainability KPIs

-

- Greenhouse Gas (GHG) Emissions. Lifecycle GHG reductions.

- Nutrient Recycling Efficienc. Effectiveness of digestate use.

- Waste Treatment Capacity. Amount of waste processed.

Feedstock Management KPIs

-

- Feedstock Utilization Rate. How efficiently feedstock is used.

- Supply Chain Reliability. Consistency of feedstock delivery.

Health, Safety & Compliance (HSE)

-

- Incident Rate. Frequency of accidents/safety breaches.

- Regulatory Compliance. Adherence to environmental laws and permits.

The Plant Main Facilities

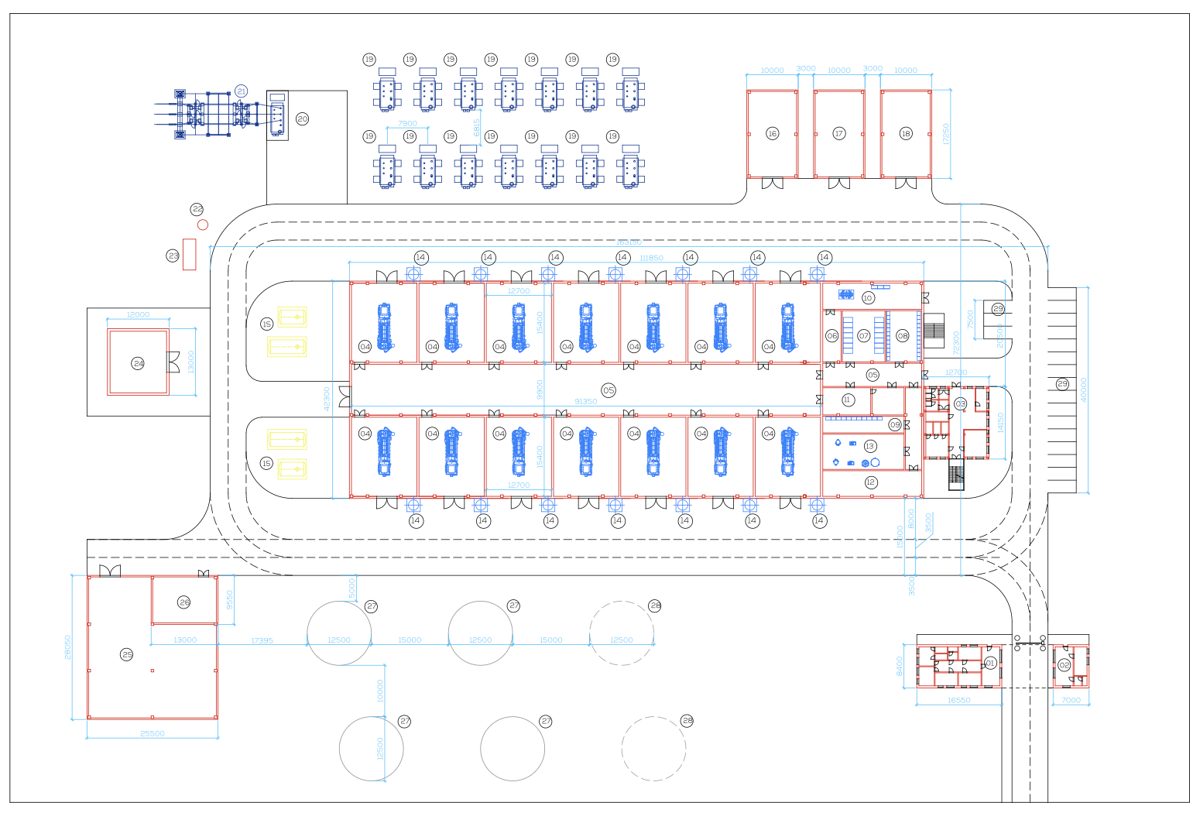

The integrated Cassava Biogas Power Plant (BPP) of the High-Quality Ethanol Plant shall be built in an area 3.528 ha (35,280m2). BPP shall be provided with a following facilities and Equipment:

-

- Concrete / Containerised Power House. For environmental and maintainbility purposes, we recommend to use Concrate Power House of 14 individual stations of 1MWh each.

- Raw-Water Tank of 1,500m3. This is an open underground concrete tank, containing all the required quantity of Raw Water piped from Du River and collected from rains.

- Treated / Demineralised-Water Tank of 1,500m3. The total daily treated water shall be used for the operations of the 100,000LPD-Ethanol Production Plant (EPP) and all following integrated facilities: Biogas Plant (BP), Biogas Power Plant (BPP) and Cassava Farm.

- Water Treatment Plant. The cooling water requirements for the MWM TCG 2020 V12 Genset involve two separate circuits: the engine jacket water circuit (flowrate of 36/56 m³/h and water volume 111 dm³ (litres)) and the intercooler coolant circuit (flowrate of 40 m³/h and water volume 28 dm³ (litres)). So a total volume of demineralised water of 1,946 dm³ (litres) or approximately storage capacity of 2 m³. The Ethanol Production Water require a total quanity of 136,575 m³/yr (i.e. 490 m³/day). So the total storage capacity of 1,500m3 sufficient to secure the daily water need of the whole Ethanol Plant for at least 3 days.

Biogas Power Plant Layout

Power Plant Designs Gallery